is drop testing impact testing|durability drop test : factories Here are four benefits of using drop machines to conduct ASTM standard tests: Precision: High precision in controlling drop height, velocity, and impact forces, ensuring consistent and reliable test results. Safety: The design of the drop . Downloads de tabelas do Brasileirão e Copa do Brasil em Excel. Planilha em Excel da Copa do Brasil 2024. 1 arquivo(s) 4.32 MB. Planilha em Excel da Copa do Brasil 2024 Grátis. Tabela de Rivalidades no Brasileirão. 1 arquivo(s) 676.23 KB. .

{plog:ftitle_list}

WEBLordosis is the inward curvature of a portion of the lumbar (lower back) and cervical (upper back) spine. These normal “lordotic curves” of the spine ( secondary .

impact strength tester

Drop testing is a procedure used to evaluate how a package and its contents react to impacts such as free-falls, tumbles, and other types of handling during . Drop weight and puncture impact testing evaluate the impact resistance of materials used in sports equipment. For instance, drop weight testing helps assess .Under controlled laboratory conditions, impact testing may be used to validate designs on prototype or OEM components to ensure they meet product durability and safety requirements. The drop-weight impact test, also known as the Pellini test, uses a weight suspended over a simply supported horizontal test specimen and then dropped to produce the impact. A tube or rails guide the weight during its “free .

Here are four benefits of using drop machines to conduct ASTM standard tests: Precision: High precision in controlling drop height, velocity, and impact forces, ensuring consistent and reliable test results. Safety: The design of the drop . The Verdict. In the end, it's not about which method is better; it's about what suits your needs. Are you in a hurry, looking for a rapid assessment? Dart Impact Testing is your sidekick. Are you in it for the long haul, wanting .

8 salt spray lane cape elizabeth

Drop testing is a vital evaluation technique used to determine the robustness of packaging under conditions that mimic the stresses and impacts experienced during transit, handling, and storage. In the drop test, Linkotest’s devices are subjected to free fall and sudden impact conditions from different heights and angles. Your product must withstand specified conditions and be tested repeatedly until a failure is found.Impact tests are short-term tests which provide information on the failure behavior of materials or components subjected to rapid loading and at varying temperatures. The testing systems . Drop testing is a critical process in product development, ensuring that items can withstand real-world impacts. This guide delves into the science behind drop testing, .

By following packaging drop test standards, this method helps companies evaluate and improve their packaging’s impact resistance, aligning with industry benchmarks for safety and reliability. . Conducting the Drop Test: A drop testing machine or a free-fall method is used to ensure precise and repeatable drops. The method of dropping .As conclusion, for drop testing and dynamic impact observation the synchronous and non-contact measurement method using a MPV Multipoint Vibrometer is a valuable way to assess the dynamic impact response. The .

The drop weight impact test method, as shown in Figure 4(a), raises the impactor to a certain height and releases it, causing a test specimen to be impacted by the drop. This method is the most popular for low-velocity .Drop Weight Impact Testing Machine. Impact Tester for Plastics, Composite, Light Alloys and Components. Instron Dynatup drop weigh impact testing machine next generation is the Instron 9400 Series. A drop weight impact testing machine is used to determine the energy required to break or damage a material in which a defined weight falls onto a .A plastic film impact testing machine, like the FDT-01 Falling Dart Impact Tester from Cell Instruments, is designed to perform drop weight impact tests accurately and efficiently. This machine is essential for industries that rely on high-quality materials for their products. Rough surfaces have a greater impact in drop testing because: The bumps on the surface act as point contacts and concentrate the load on the test unit during the drop. Rough surfaces tend to grip the test subject’s casing, preventing the device from sliding, which would otherwise dissipate impact energy through rotational motion. .

The drop-weight impact test, also known as the Pellini test, uses a weight suspended over a simply supported horizontal test specimen and then dropped to produce the impact. A tube or rails guide the weight during its “free-fall” onto the specimen. Unlike Charpy and Izod tests, the height of the weight before and after it strikes the test .

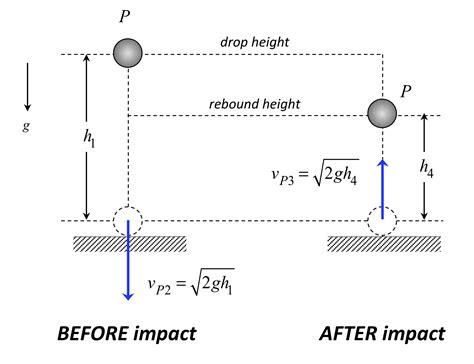

Drop Weight Impact Test. A second method was to drop a weight in a vertical direction, with a tube or rails to guide it during the "free fall." Once again, with the height and weight known, impact energy can be calculated. In the early days, there was no way to measure impact velocity, so engineers had to assume no friction in the guide .

What Testing Equipment is critical for Impact Test results . Pendulum Impact Testing machines and Drop Weight Testers are both critical to validating the performance of materials. However, there are differences between the two instruments that determine which application is best suited to each. Difference between a Pendulum Impact Testing .The role of standards in the impact assessment of drop test results is comprehensive, affecting everything from test consistency to regulatory compliance, market access, innovation, and consumer trust. By providing a structured framework for evaluating and improving packaging, standards ensure that products can withstand the rigors of transit .With the combined use of a drop weigh impact testing machine equipped with Bluehill ® Impact Software, tensile impact accessories, High Speed Camera and Digital Image Correlation software, it is possible to evaluate the longitudinal strain of the specimen when impacted under tensile-Impact conditions.

impact drop test calculation

Drop-Weight and Charpy V-Notch Tests. Examining the Charpy Effect Metals’ impact resistance or toughness can be measured by subjecting them to impact testing, which involves measuring the amount of energy absorbed by the material before it breaks. To determine if the impact energy is affected by temperature, the test is carried out at a range of temperatures. An example of such a methodology is the drop weight impact test, which entails subjecting materials to controlled, low and high-energy impacts to ascertain their resistance to impact [9]. This testing protocol involves the release of a mass from a predetermined height onto a concrete specimen and then assessing the resultant damage [10].

As conclusion, for drop testing and dynamic impact observation the synchronous and non-contact measurement method using a MPV Multipoint Vibrometer is a valuable way to assess the dynamic impact response. The MPV-800 uses independent fiber-optical sensors which can be positioned arbitrarily around the object and – if required – can be .Drop testers have become an essential tool in product durability testing. They simulate the impact of drops and falls, ensuring that products meet rigorous standards for quality and safety.In this guide, we’ll explore the world of drop .What Testing Equipment is critical for Impact Test results . Pendulum Impact Testing machines and Drop Weight Testers are both critical to validating the performance of materials. However, there are differences between the two .An impact test is designed to replicate situations in which an object or material will react when subjected to an impact load that instantaneously causes the specimen to deform, . ISO 7765 – Performance of the weight drop test to .

A drop weight tester is a testing machine that is used to test the resistance of a material to impacts or shocks.In the drop weight impact test, a weight is dropped from a defined height onto the material to be tested using a drop weight tester. This drop generates a certain impact energy that is transferred onto the material.. Drop weight testers are available in different .ZwickRoell has been delivering high-quality impact test equipment for years. Based on this experience, ZwickRoell has developed a new drop weight tester product series under the name Amsler.. Components testing often places particular demands on a drop weight tester.The impact surface of the component is often not at an exact right angle to the direction of impact, .

The testing also improved our understanding of the impact behavior of the coatings and how to relate their low energy impact performance in drop tower tests to much higher energy impact situations .

A brief history of plastics impact testing. To detect material behaviors at high deformation speeds, impact testing is employed. Pendulum impact testers, high-speed testing equipment, and drop weight testers are all used to determine how plastics behave under impact loading.. In the past, choosing between drop weight and pendulum impact testers appeared straightforward.Drop tower testing is a form of impact testing used to measure energy absorbed by a material during high velocity impacts. The test system consists of a falling mass guided by two columns, instrumentation to measure force, fixture to hold the sample, and data collection system. This test is used for a component or an assembly. .

Drop Weight Impact Test. A second method was to drop a weight in a vertical direction, with a tube or rails to guide it during the "free fall." Once again, with the height and weight known, impact energy can be calculated. In the early days, there was no way to measure impact velocity, so engineers had to assume no friction in the guide .For vertical impact force measurement a drop tower is a commonly used structure: it contains a platform for drop-off and a set of force sensors at the bottom, typically mounted between a top and a base plate. Such drop testing requires high stiffness of the sensor array and fast rise times to correctly measure the impact peak force.ASTM D6179 and D880 typically cover the relevant impact and drop testing for these crates and unitized loads. By testing a variety of packaging configurations, teams can verify product ruggedness and optimize material selection for safe and efficient packaging. The ASTM D5276 drop test can be performed on a variety of products and packaging .

durability drop test

Drop and impact testing are just two of the dynamic testing services that Keystone Package Testing is fully equipped to perform. Our ISTA-accredited laboratory has an extensive scope of testing procedures for ASTM, ISTA, Amazon, and other international standards.

Key considerations in drop testing for packaging. Drop height and orientation: The test should replicate realistic scenarios, including the height from which packages might fall and the orientation upon impact (e.g., corner, edge, or flat). Package and content weight: The weight of the package and its contents can significantly affect the outcome of drop tests, necessitating .

drop weight impact tester

Resultado da 5 de set. de 2022 · Novo endereço. Rua 2 de Setembro, 1761 – Bairro. Itoupava Norte, Blumenau. Novo telefone: 47-3378-9066. No prédio do bairro Garcia, onde costumava funcionar a CPP, ficará a sede da DIC (Divisão de Investigações Criminais). Participe do grupo e receba as principais .

is drop testing impact testing|durability drop test